Blast Chillers

Advantages of a Blast Chiller / Freezer

What are benefits of using a Blast Chiller?

Maintaining food quality

Prevent food shrinkage

Increase menu choice and service

Achieve Food Safety Standards

Improve shelf life

Save and profit

By reducing the period of time when food temperature naturally accelerates the rate at which harmful bacteria grows, chefs and producers are able to extend the shelf life of food products. This can significantly improve sales and availability, whilst reducing food waste.

Gain peace of mind

TASTY AND QUICKLY, TOGETHER FOR THE FIRST TIME.

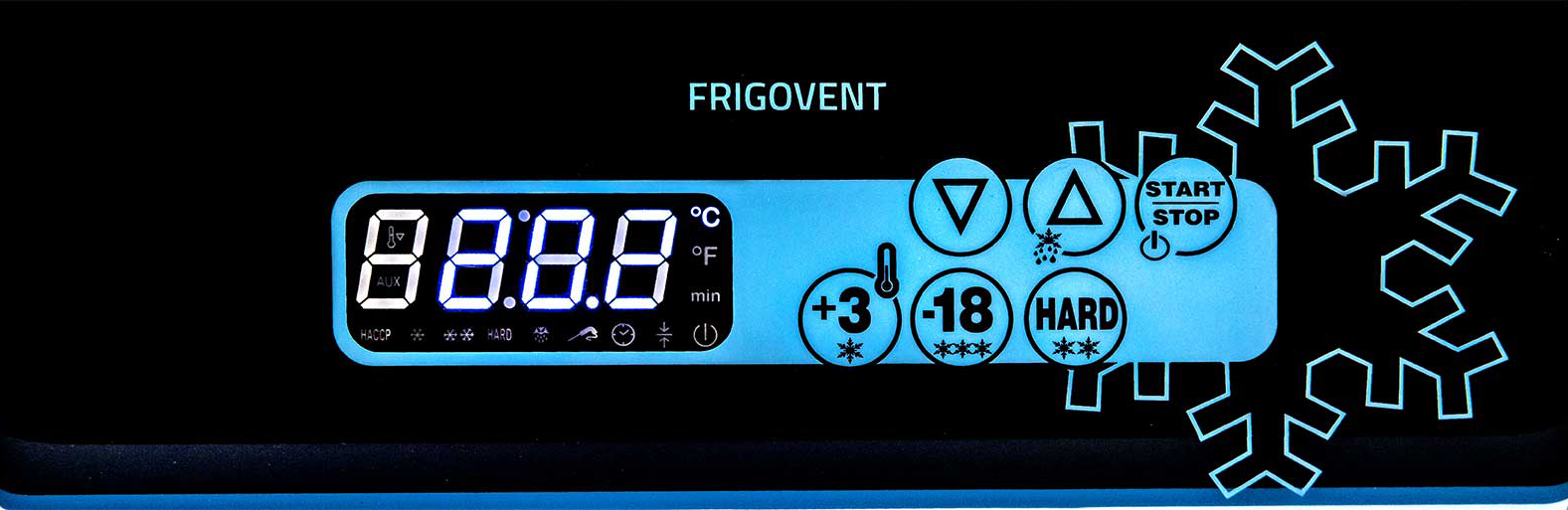

Government standards state that all cooked food, which will not be consumed straight away (normally within 2 hours), must be cooled as quickly as possible to reduce the growth of harmful bacteria. By using a Blast Chiller, cooked food products reaching a temperature of +3°C can be safely stored in a refrigerator without affecting the performance of the refrigeration equipment and the condition of other food stuffs held in the cabinet or cold room.

Save time and money

Efficient and easy to use

Once in place and used appropriately, a Blast Chiller quickly becomes an essential piece of the kitchen or production equipment enabling the efficient use of resources, increase scale of purchasing ingredients and larger batch production. A Blast Chiller enables the safe storage of pre-prepared foods when staff are less busy. Larger quantities of ingredients can be purchased, prepared and chilled for storage without sacrificing the food or unnecessary food waste. Save energy by making more efficient use of your cooking equipment by fully utilizing capacity and only at times when the equipment is needed. Blast Chillers are not known for low energy consumption, since they are designed to reduce the temperature of food as quickly as possible. However, energy saving can be made by using this type of refrigeration by using cooking or baking equipment to full capacity, then chilling and storing food products accordingly.

What are the benefits of using a Blast Freezer ( Shock Freezer)?

Prima Line

Frigovent Prima Line Blast Chillers are the professional solution for HoReCa industry, from the small bakeries and patisseries, gastronomy, hotels and restaurants.

Energy Line

Class Line